Where to buy cassava processing machine in China?

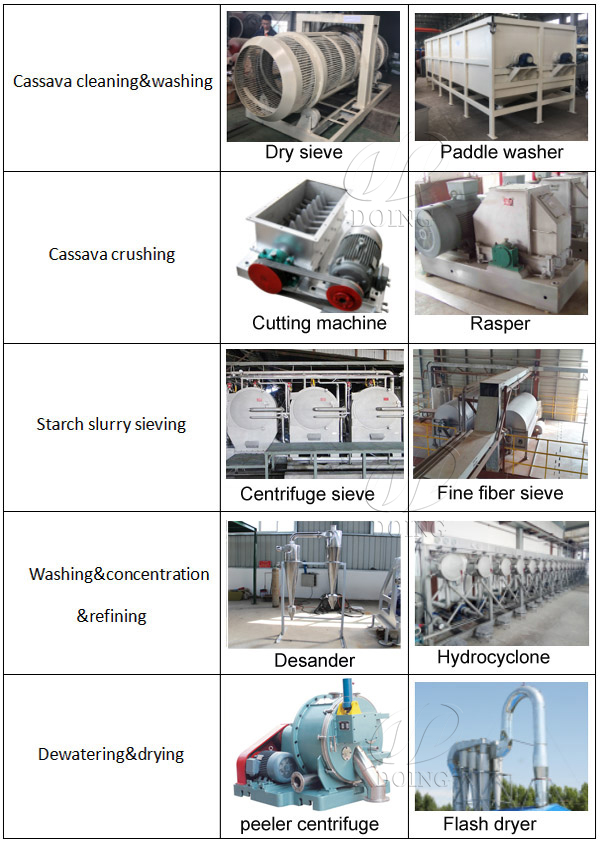

Nigeria is an important cassava producer. However, Cassava processing in Nigeria still largely depends on manual processing, for the overall level of agricultural mechanization in Africa is still in its infancy. In Nigeria, most of the cassava cultivation or cassava processing still relies on human resources. However, in recent years, with the development of the economy, Nigeria has more and more demand for mechanical cassava processing machine, especially cassava processing machine in China manufactured. So where to buy cassava processing machine in China? Cassava processing machine First, the recommendation of industry professionals Each industry has corresponding professionals. If know professionals in the industry, you can ask them to give professional advice according to your purchasing needs, and ask them to recommend several professional and cost-effective manufacturers of cassava processing machine in China for you to contact. And if possible, it is best to in