Cassava starch production in Nigeria equipment

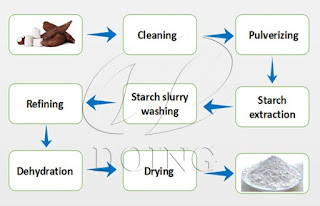

Cassava starch production in Nigeria Cassava - Conveying - De-mixing - Cleaning - Drum cleaning - Primary crushing - Secondary crushing - Screening - Cellulose separation - Protein separation - Sand removal - Fine screening - Dehydration - - Feeding - Starch drying - finished screen - air-cooled - packaging. Cassava starch production line List of cassava starch extraction machine for cassava starch production in Nigeria: (1) Vertical hoist (2) Vertical cleaning machine (3) Horizontal cleaning machine (4) Buffering silo (5) Belt hoist (6) Measuring weighing machine (7) Vapor peeling machine and gas storage tank (8) Air compressor (9) Screw conveyor (10) Dry brush peeling machine (11) Surf cleaning machine (12) Manual tiller Machine (13) bucket elevator (14) buffer silo (15) slicer (16) surf cleaning machine (17) blanching machine (18) screw conveyor (23) Cooling machine (20) chain bucket hoist (21) cooking machine (22) screw conveyor (23) feeding mixer (24) screw conveyor (25) ag