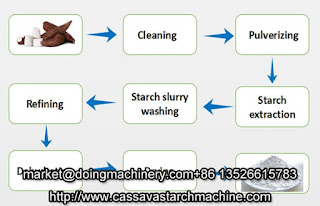

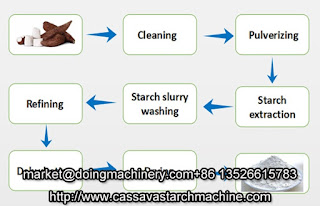

Professional cassava starch production line

The production process of cassava starch production line is divided into the following part: Weighing and conveying, cleaning, washing, grinding, separation, desanding, concentration and refining, dehydration, starch drying and packaging processes. Cassava starch production line 1. Raw material weighing and conveying Due to the short storage time of cassava roots, it is essential to complete the entire cassava starch production line as soon as possible. The newly harvest cassava is firstly weighed by the weighbridge and stored in the cassava yard for storage. Then the weighted cassava is transported by a belt conveyor to cleaning machine for processing. 2. Washing: Paddle washing machine is adopted for washing process for cassava starch production line. This machine is suitable for the cleaning of cassava, and can basically remove the clay and sand on the surface of raw materials. The whole machine adopts the counter-current washing principle, the cleaning effect is good, and