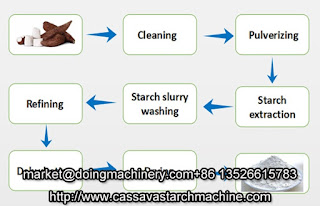

Cassava starch manufacturing process

In cassava starch manufacturing process, we use physical separation method to process cassava starch. By taking use of the property that cassava starch is insoluble in cold water and has a specific gravity greater than water, Doing Company use water and professional cassava starch processing equipment to separate the starch from the water suspension to achieve the purpose of recovering the starch.

The following is the introduction of the cassava starch manufacturing process

1. Cleaning: The newly harvested cassava roots contains weed, stone, siol, sand and other debris. Therefore they need to be cleaned first before further processing. The most widely used cassava starch processing machine for cleaning in cassava starch manufacturing process is dry sieve. Designed with multiple inner spiral, this machine can achieve the transportation of cassava during the cleaning process.

2. Wahing: The washing process in cassava starch manufacturing process is used for removing the attached soil, sand, dirt and so on with paddle washing machine and wahsing water. DOING paddle washing machine adopts the counterwater washing principle to save water and improve washing effect.

3. Grinding: Cassava roots are grinded into starch slurry so that the free starch is released from cassava cell. DOING rasper is a high efficient machine with high grinding rate over 94% in cassava starch manufacturing process.

4. Starch slurry and slag separation: This cassava starch manufacturing process is mainly used to separate fiber from starch. It is required that the starch residue contains less than 35% starch after separation process in cassava starch making production plant, wherein the free starch contains less than 5%, and the fiber impurity content of the milk slurry is less than 0.05%.

5. Concentration and refining: Then the starch slurry is injected into the hydrocyclon station through the starch pump for concentration and refining in cassava starch manufacturing process. This cassava starch processing machine is mainly used for washing, refining and concentration of cassava starch pulp. The whole system integrates various functions such as concentration, recovery, washing and separation which is simple in process, stable and reliable in product quality.

6. Wet starch dewatering: Peeler centrifuge is a widely used cassava starch processing machine whose main function is the separation of solid and liquid in cassava starch manufacturing process. This cassava dewatering machine features with good starch dewatering effect and stable water content of wet starch.

7. Drying and packing: This is the final processing procedure in cassava starch manufacturing process. The dewatered cassava starch enters into flash dryer by feed conveyor and mixs with the high speed hot air flow, and the drying process is completed in just a few seconds by heat exchange. After that, the dryed cassava starch are packed into 25kg or 50kg according to different requirements.

Click here to give you the best price

Whatsapp/Phone:+86 135 2661 5783

Contact: Ms Elina

Email: market@doingmachinery.com

Tel: 0086 371 5677 1822

View more:

cassava starch production in Nigeria

cassava starch making production plant

cassava starch processing machine

cassava starch production in Vietnam

Cassava starch manufacturing process

The following is the introduction of the cassava starch manufacturing process

1. Cleaning: The newly harvested cassava roots contains weed, stone, siol, sand and other debris. Therefore they need to be cleaned first before further processing. The most widely used cassava starch processing machine for cleaning in cassava starch manufacturing process is dry sieve. Designed with multiple inner spiral, this machine can achieve the transportation of cassava during the cleaning process.

2. Wahing: The washing process in cassava starch manufacturing process is used for removing the attached soil, sand, dirt and so on with paddle washing machine and wahsing water. DOING paddle washing machine adopts the counterwater washing principle to save water and improve washing effect.

3. Grinding: Cassava roots are grinded into starch slurry so that the free starch is released from cassava cell. DOING rasper is a high efficient machine with high grinding rate over 94% in cassava starch manufacturing process.

Cassava grinding machine

4. Starch slurry and slag separation: This cassava starch manufacturing process is mainly used to separate fiber from starch. It is required that the starch residue contains less than 35% starch after separation process in cassava starch making production plant, wherein the free starch contains less than 5%, and the fiber impurity content of the milk slurry is less than 0.05%.

5. Concentration and refining: Then the starch slurry is injected into the hydrocyclon station through the starch pump for concentration and refining in cassava starch manufacturing process. This cassava starch processing machine is mainly used for washing, refining and concentration of cassava starch pulp. The whole system integrates various functions such as concentration, recovery, washing and separation which is simple in process, stable and reliable in product quality.

6. Wet starch dewatering: Peeler centrifuge is a widely used cassava starch processing machine whose main function is the separation of solid and liquid in cassava starch manufacturing process. This cassava dewatering machine features with good starch dewatering effect and stable water content of wet starch.

Cassava starch dewatering machine

7. Drying and packing: This is the final processing procedure in cassava starch manufacturing process. The dewatered cassava starch enters into flash dryer by feed conveyor and mixs with the high speed hot air flow, and the drying process is completed in just a few seconds by heat exchange. After that, the dryed cassava starch are packed into 25kg or 50kg according to different requirements.

Click here to give you the best price

Whatsapp/Phone:+86 135 2661 5783

Contact: Ms Elina

Email: market@doingmachinery.com

Tel: 0086 371 5677 1822

View more:

cassava starch production in Nigeria

cassava starch making production plant

cassava starch processing machine

cassava starch production in Vietnam

Comments

Post a Comment