Cassava starch processing machine

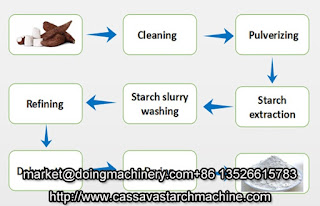

The production process of cassava starch is a physical separation process, which separates the starch from fiber, protein and inorganic materials. In the process of production, we usually separate starch from starch suspension according to the property of starch, that is, starch is insoluble in cold water and starch proportion is greater than water. By using special cassava starch processing machine , we can achieve the goal of separation starch. 1. Cleaning machine: The newly harvested cassava roots contains weed, stone, siol, sand and other debris. Therefore they need to be cleaned first before further processing. Dry sieve is the most widely used cassava starch processing machine for cleaning in cassava starch processing plant . Designed with multiple inner spiral, this machine can achieve the transportation of cassava during the cleaning process. 2. Wahing machine: The cassava starch processing machine for washing in cassava processing plant is used for removing the attached so