Cassava starch production line and cassava starch machine

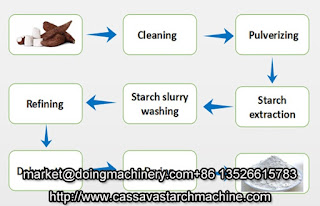

The cassava starch production line of Doing Company adopts the wet processing technology of starch production without any additives. The process is operated automatically from the whole process of cleaning, washing, grinding, separating, desanding, concentration and refining, dehydration and drying of raw materials.

Here are the detail introduction of machines used in cassava starch production line:

1. Cassava cleaning and washing process

The machine used for cassava cleaning and washing in cassava starch production line includes the dry sieve and rotary washing machine. These machines carry out multi-stage cleaning of raw materials (cassavaes), fully remove the skin sediment and improve the purity of raw materials. These machine features with continuous work without burden, multiple cleaning processes have high cleanliness and low energy consumption.

2.Cassava grinding process

Grinding is an important process in cassava starch production line. Therefore grinding machine is an important cassava starch processing machine. DOING raper is an high efficient grinding machine which can fully grind cassava into slurry. This machine adopts bidirectional grinding design which ensures a higher grinding coefficient.

3. Starch and slag separating process

The next machine used in cassava starch production line is the centrifuge sieve and the fine fiber sieve. The centrifuge sieve is mainly used to separate the fiber and starch slurry. While the fine fiber sieve is used to further filter the small fibers.

4. Desanding process

This process in cassava starch production line is mainly for remove the sand content out of cassava slurry for it has a bad influence on the taste of cassava starch. The desander utilizes the different specific gravity between the cassava starch and sand to remove the sand.

5. Concentration and purification process

The main machine of this section is starch cyclone station. The main function of this machine in cassava starch production line is high efficiency concentration and purification, separation of non-starch substances, improve the quality of starch whiteness. And the main features of this machine is easy operation, convenient maintenance and long service life.

6. Starch milk dewatering process

Cassava dewater machine is mainly used for reduce the water content of cassava starch in cassava starch production line. The most widely used machine for this process is peeler centrifuge which is a continous operation machine. Afte the dewatering process, the water content of wet starch is about 38%.

7. Cassava starch drying process

The finally process in cassava starch production line is drying process and the machine is flash dryer. The material contact parts of this machine is made of stainless steel which guarantees the high standards of the final cassava starch.

Click here to give you the best price

Whatsapp/Phone:+86 135 2661 5783

Contact: Ms Elina

Email: market@doingmachinery.com

Tel: 0086 371 5677 1822

View more:

cassava starch processing machinery manufacturer

cassava starch production in Nigeria

cassava starch production in Vietnam

cassava starch manufacturing process

Cassava starch production line

Here are the detail introduction of machines used in cassava starch production line:

1. Cassava cleaning and washing process

The machine used for cassava cleaning and washing in cassava starch production line includes the dry sieve and rotary washing machine. These machines carry out multi-stage cleaning of raw materials (cassavaes), fully remove the skin sediment and improve the purity of raw materials. These machine features with continuous work without burden, multiple cleaning processes have high cleanliness and low energy consumption.

2.Cassava grinding process

Grinding is an important process in cassava starch production line. Therefore grinding machine is an important cassava starch processing machine. DOING raper is an high efficient grinding machine which can fully grind cassava into slurry. This machine adopts bidirectional grinding design which ensures a higher grinding coefficient.

Cassava starch machine

3. Starch and slag separating process

The next machine used in cassava starch production line is the centrifuge sieve and the fine fiber sieve. The centrifuge sieve is mainly used to separate the fiber and starch slurry. While the fine fiber sieve is used to further filter the small fibers.

4. Desanding process

This process in cassava starch production line is mainly for remove the sand content out of cassava slurry for it has a bad influence on the taste of cassava starch. The desander utilizes the different specific gravity between the cassava starch and sand to remove the sand.

5. Concentration and purification process

The main machine of this section is starch cyclone station. The main function of this machine in cassava starch production line is high efficiency concentration and purification, separation of non-starch substances, improve the quality of starch whiteness. And the main features of this machine is easy operation, convenient maintenance and long service life.

Cassava starch drying machine

6. Starch milk dewatering process

Cassava dewater machine is mainly used for reduce the water content of cassava starch in cassava starch production line. The most widely used machine for this process is peeler centrifuge which is a continous operation machine. Afte the dewatering process, the water content of wet starch is about 38%.

7. Cassava starch drying process

The finally process in cassava starch production line is drying process and the machine is flash dryer. The material contact parts of this machine is made of stainless steel which guarantees the high standards of the final cassava starch.

Click here to give you the best price

Whatsapp/Phone:+86 135 2661 5783

Contact: Ms Elina

Email: market@doingmachinery.com

Tel: 0086 371 5677 1822

View more:

cassava starch processing machinery manufacturer

cassava starch production in Nigeria

cassava starch production in Vietnam

cassava starch manufacturing process

Comments

Post a Comment