Cassava starch manufacturing process machine

The cassava starch manufacturing process of Doing Company adopts the wet processing technology of starch production without any additives. The process is operated automatically from the whole process of cleaning, washing, grinding, separating, desanding, concentration and refining, dehydration and drying of raw materials.

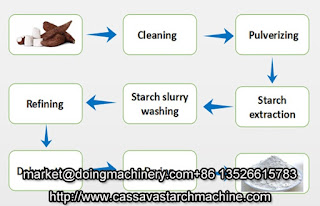

Cassava starch manufacturing process

The following is the detail introduction of cassava starch manufacturing process

1. Cassava cleaning section

Dry sieve is the firstly used cassava starch processing machine in cassava starch manufacturing process. It meanly remove the dirt, stand, small stones, weeds and other impurities on the surface of the cassav

2. Cassava washing section

Paddle washing machine is the most widely used cassava washing machine whose main function is to further wash the attached dirt, mud, sand, ect in cassava starch manufacturing process. This machine adopts the countercurrent washing principle so that the material can be washed completed and thoroughly.

3. Crushing section

This is the most important step in cassava starch manufacturing process. The rasper is used to crush the cassava into slurry so as to release the free starch in the cassava cell. The extraction rate of starch is determined by this machine. DOING rasper is an advanced crushing machine which fully absorbs technology from home and abroad, and the breakage rate can reach at around 95%.

Cassava crushing machine

4. Starch slurry separating section

Starch separating is another key unit for cassava starch manufacturing process which has an important effect on the extraction rate of cassava starch. The good centrifuge sieve and processing technology can extract the free starch from the cassava cells.

Doing Company adopts four-stage centrifugal sieve group can ensure that most of the free starch is collected into the extraction system, which fully guarantees the extraction rate of starch.

5. Desanding section

This process is mainly for remove the sand content out of cassava slurry for it has a bad influence on the taste of cassava starch in cassava starch manufacturing process. The desander utilizes the different specific gravity between the cassava starch and sand to remove the sand.

6. Concentration and refining section

After desanding, the cassava starch enters into hydrocyclone station. This process is mainly used for separate the fiber, protein and cell sap from starch in cassava starch manufacturing process. DOING full hydrocyclone technology can achieve the concentration, recycling and refining of cassava milk.

Cassava starch separating machine

7. Dehydrating section

And the next machine for cassava starch manufacturing process is the peeler centrifuge which is a widely used starch dehydration machine. Due to this cassava starch processing machine absorbs the foreign and domestic advanced technology, it offers high dewatering rate.

8. Drying section

And the drying process is carried out by the principle of negative pressure in cassava starch manufacturing process. The wet starch is mixed with hot air into the air duct, and after entering the drying requirement, it enters the cyclone separator and is then packaged into the storage.

Chat on line

Whatsapp/Phone:+86 135 2661 5783

Contact: Ms Elina

Email: market@doingmachinery.com

Tel: 0086 371 5677 1822

View more:

cassava starch production in Nigeria

cassava starch production in Vietnam

cassava starch processing machine

cassava starch processing plant

Comments

Post a Comment