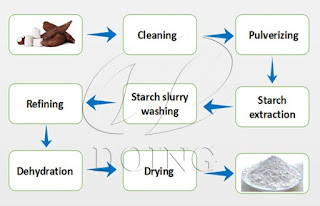

Cassava starch manufacturing process and processing machinery

The cassava starch processing machine used in cassava starch manufacturing process are as follows:

Forklift, screw cleaning machine, paddle washing machine, cassava grinding machine, multi stage centrifuge sieve, fine fiber sieve, sand removal machine, starch enrichment and refining system, peeler centrifuge, flash dryer and packing machine

1. Cleaning and washing: Cassava root needs to be processed immediately after harvest because the root is highly perishable, and the enzyme process accelerates deterioration in 1-2 days. Cleaning in cassava starch manufacturing process serves to remove the sediments attached on cassava and outer peels of cassava. Then cleaned cassava enters into paddle washing machine for further remove the soil, dirt and other impurities with countercurrent washing method.

2. Rasper for cassava crushing - DOING rasper is the an advanced cassava grating machine on the market. By introducing Germany Optibelt and Sweden SKF bearing, this cassava starch processing machine not only advance in technology but also excellent in performance. Its grating rate is more than 94% in cassava starch manufacturing process.

3. Cassava starch screening process

The original starch slurry after being crushing need to be screened to separate the starch milk from the fiber in cassava starch manufacturing process. At the same time, the fiber needs to recovery of starch by detergent. The purpose of separating is achieved by centrifuge sieve and fine fiber sieve.

4. Sand removal machine - The desander cyclone is based on the principle of centrifugal separation to remove sand, thus to improve the taste of starch and ensure the quality of starch in cassava starch manufacturing process.

5. Hydrocyclone station - The hydrocyclone station is used for removing protein and other impurities in cassava starch manufacturing process. With its unique structure and different combination forms, this cassava starch processing machine can independently complete the separation, washing, clarification, concentration, screening and other operational tasks in starch processing.

6. Cassava starch dehydrating process

After the separation process, the refined starch milk still contains a lot of water, so it must be dehydrated to facilitate drying. In cassava starch manufacturing process, peeler centrifuge is often used for dehydrating. The moisture content of wet starch after dehydration is required to be about 38%.

7. Starch drying and packing process

Drying is carried out after the dehydrating process in cassava starch manufacturing process. Flash dryer is the widely used cassava starch drying machine which features with high heat exchange rate and short drying time. The water content of starch product is about 13.5% through drying.

Cassava starch processing machine used in cassava starch manufacturing process has the characteristics of energy-saving, no additives, health and environmental protection, saving manpower and improving efficiency. The development and manufacture of cassava starch extraction machine are a perfect upgrade and comprehensive overtaking of the traditional manual milling process.

Chat on line / Whatsapp/Phone:+86 135 2661 5783

Contact: Ms Elina

Email: market@doingmachinery.com

Tel: 0086 371 5677 1822

View more:

cost of cassava processing equipment

cost of cassava processing plant in Nigeria

cassava starch production in Nigeria

cassava starch production line

Forklift, screw cleaning machine, paddle washing machine, cassava grinding machine, multi stage centrifuge sieve, fine fiber sieve, sand removal machine, starch enrichment and refining system, peeler centrifuge, flash dryer and packing machine

Cassava starch manufacturing process

1. Cleaning and washing: Cassava root needs to be processed immediately after harvest because the root is highly perishable, and the enzyme process accelerates deterioration in 1-2 days. Cleaning in cassava starch manufacturing process serves to remove the sediments attached on cassava and outer peels of cassava. Then cleaned cassava enters into paddle washing machine for further remove the soil, dirt and other impurities with countercurrent washing method.

2. Rasper for cassava crushing - DOING rasper is the an advanced cassava grating machine on the market. By introducing Germany Optibelt and Sweden SKF bearing, this cassava starch processing machine not only advance in technology but also excellent in performance. Its grating rate is more than 94% in cassava starch manufacturing process.

3. Cassava starch screening process

The original starch slurry after being crushing need to be screened to separate the starch milk from the fiber in cassava starch manufacturing process. At the same time, the fiber needs to recovery of starch by detergent. The purpose of separating is achieved by centrifuge sieve and fine fiber sieve.

Cassava grating machine

4. Sand removal machine - The desander cyclone is based on the principle of centrifugal separation to remove sand, thus to improve the taste of starch and ensure the quality of starch in cassava starch manufacturing process.

5. Hydrocyclone station - The hydrocyclone station is used for removing protein and other impurities in cassava starch manufacturing process. With its unique structure and different combination forms, this cassava starch processing machine can independently complete the separation, washing, clarification, concentration, screening and other operational tasks in starch processing.

6. Cassava starch dehydrating process

After the separation process, the refined starch milk still contains a lot of water, so it must be dehydrated to facilitate drying. In cassava starch manufacturing process, peeler centrifuge is often used for dehydrating. The moisture content of wet starch after dehydration is required to be about 38%.

Cassava starch separating machine

7. Starch drying and packing process

Drying is carried out after the dehydrating process in cassava starch manufacturing process. Flash dryer is the widely used cassava starch drying machine which features with high heat exchange rate and short drying time. The water content of starch product is about 13.5% through drying.

Cassava starch processing machine used in cassava starch manufacturing process has the characteristics of energy-saving, no additives, health and environmental protection, saving manpower and improving efficiency. The development and manufacture of cassava starch extraction machine are a perfect upgrade and comprehensive overtaking of the traditional manual milling process.

Chat on line / Whatsapp/Phone:+86 135 2661 5783

Contact: Ms Elina

Email: market@doingmachinery.com

Tel: 0086 371 5677 1822

View more:

cost of cassava processing equipment

cost of cassava processing plant in Nigeria

cassava starch production in Nigeria

cassava starch production line

Comments

Post a Comment