Cassava starch processing machine in cassava starch production line

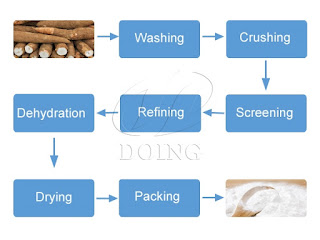

The cassava starch processing machine used in cassava starch processing plant are as follows:

Forklift, screw cleaning machine, paddle washing machine, cassava grinding machine, multi stage centrifuge sieve, fine fiber sieve, sand removal machine, starch enrichment and refining system, peeler centrifuge, flash dryer and packing machine

1. Cassava cleaning process:

This is the first cassava starch processing machine in cassava starch processing plant. The cassava is transported into dry sieve by belt conveyor for cleaning. The sand, soil, weed, stone and other impurities are removed in this process.

2. Cassava washing process:

The cleaned cassava is then transported into paddle washing machine for further removing sand, soil, dirt and other attached debris. By adopting countercurrent washing principle, this cassava starch processing machine can effectively remove the impurities.

3. Rasper for cassava crushing: Crushing is the most important in cassava starch production line, therefore the rasper is the most important cassava starch processing machine. The main function of rasper is to extract starch as much as possible to get high yield of cassava starch. DOING rasper is an advanced machine which introduces Sweden SKF bearing and Germany Optibelt. The breaking rate can reach up to 95%.

4. Starch and residue separation: Separation is mainly used for removing fibers out of starch slurry. The efficient cassava starch processing machine used for the separation of starch from cellulose fiber is the centrifuge sieve and fine fiber sieve. The starch slurry is put in a conical basket and centrifugal action separates the starch dispersion from the fibrous pulp.

5. Starch slurry desanding: The starch slurry contains sand which need to be removed by a sand remover. This cassava starch processing machine for desanding takes use of density separation method to achieve the purpose of sand removal.

6. Starch concentration and refining: The function is to separate the protein, fiber, cell sap and other impurities from the starch slurry, thereby achieving the purpose of washing, refining and concentrating the starch milk. Doing Company can provide advanced full hydrocyclone cassava starch processing machine.

click here to see Cassava starch processing plant running video

6. Dehydrating process

After the concentration and refining process, the concentrated starch milk still contains a large amount of water, and thus must be dehydrated to facilitate drying. At present, the peeler centrifuge is widely used cassava starch processing machine for dewatering. It is required that the moisture content of the wet starch after dehydration is less than 38%.

7. Drying and packing process

The wet starch dehydrated by peeler centrifuge is transferred to flash dryer for drying. It is required to after drying by cassava starch processing machine, the moisture content of the finished starch is about 13.5%. Then the starch is packed for storage. And this process requires a sufficient number of bags, a firm package, and timely storage.

Related reading: How much is cassava processing machine ?

Projce: 20TPD cassava starch processing plant project in Nigeria

Tel:0086 371 5677 1822

Email:sales@doingmachinery.com

WhatsApp/phone:+86 135 2661 5783

Read more:

http://www.cassavaprocessing.com

Cassava processing plant

Forklift, screw cleaning machine, paddle washing machine, cassava grinding machine, multi stage centrifuge sieve, fine fiber sieve, sand removal machine, starch enrichment and refining system, peeler centrifuge, flash dryer and packing machine

Cassava starch processing machine

1. Cassava cleaning process:

This is the first cassava starch processing machine in cassava starch processing plant. The cassava is transported into dry sieve by belt conveyor for cleaning. The sand, soil, weed, stone and other impurities are removed in this process.

2. Cassava washing process:

The cleaned cassava is then transported into paddle washing machine for further removing sand, soil, dirt and other attached debris. By adopting countercurrent washing principle, this cassava starch processing machine can effectively remove the impurities.

Rasper

3. Rasper for cassava crushing: Crushing is the most important in cassava starch production line, therefore the rasper is the most important cassava starch processing machine. The main function of rasper is to extract starch as much as possible to get high yield of cassava starch. DOING rasper is an advanced machine which introduces Sweden SKF bearing and Germany Optibelt. The breaking rate can reach up to 95%.

4. Starch and residue separation: Separation is mainly used for removing fibers out of starch slurry. The efficient cassava starch processing machine used for the separation of starch from cellulose fiber is the centrifuge sieve and fine fiber sieve. The starch slurry is put in a conical basket and centrifugal action separates the starch dispersion from the fibrous pulp.

Centrifuge sieve

5. Starch slurry desanding: The starch slurry contains sand which need to be removed by a sand remover. This cassava starch processing machine for desanding takes use of density separation method to achieve the purpose of sand removal.

6. Starch concentration and refining: The function is to separate the protein, fiber, cell sap and other impurities from the starch slurry, thereby achieving the purpose of washing, refining and concentrating the starch milk. Doing Company can provide advanced full hydrocyclone cassava starch processing machine.

click here to see Cassava starch processing plant running video

Peeler centrifuge

6. Dehydrating process

After the concentration and refining process, the concentrated starch milk still contains a large amount of water, and thus must be dehydrated to facilitate drying. At present, the peeler centrifuge is widely used cassava starch processing machine for dewatering. It is required that the moisture content of the wet starch after dehydration is less than 38%.

7. Drying and packing process

The wet starch dehydrated by peeler centrifuge is transferred to flash dryer for drying. It is required to after drying by cassava starch processing machine, the moisture content of the finished starch is about 13.5%. Then the starch is packed for storage. And this process requires a sufficient number of bags, a firm package, and timely storage.

Related reading: How much is cassava processing machine ?

Projce: 20TPD cassava starch processing plant project in Nigeria

Tel:0086 371 5677 1822

Email:sales@doingmachinery.com

WhatsApp/phone:+86 135 2661 5783

Read more:

http://www.cassavaprocessing.com

Cassava processing plant

Comments

Post a Comment