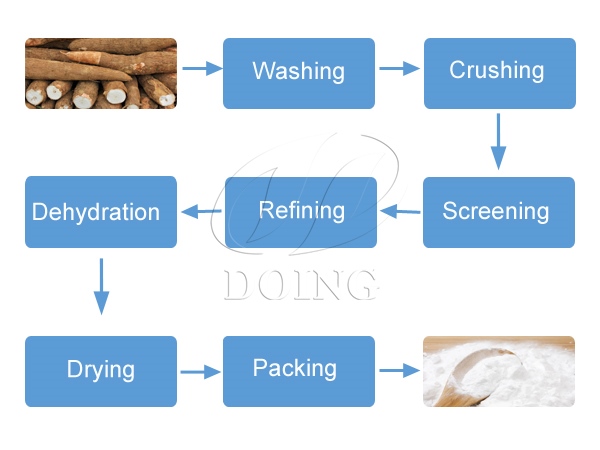

How to produce starch from cassava with cassava starch processing machine?

The cassava starch production line of Doing Company adopts the advanced and most widely used cassava processing machine which not only features with high production stability, strong adaptability, good controllability, easy maintenance, but with high extraction rate of starch, high starch quality, and well praised by manufacturers and product consumers. So how to produce starch from cassava?

Cleaning and washing

Cassava cleaning process of how to produce starch from cassava usually adopts two machine: dry sieve and paddle washer to get a better cleaning effect, fully filter out the leafs, sand and other dirty on cassava.

The second is the grating

The cleaned cassava is pulverized by a grating machine, which blows the structure of the raw material in the process of how to produce starch from cassava, so that the tiny starch granules can be disintegrated and separated from the cassava roots. The starch has been substantially freed out and becomes a slurry mixture.

Starch and residue separation

Separation is mainly used for removing fibers out of starch slurry in the process of how to produce starch from cassava. The efficient machines used for the separation of starch from cellulose fiber is the centrifuge sieve and fine fiber sieve. The starch slurry is put in a conical basket and centrifugal action separates the starch dispersion from the fibrous pulp.

Cyclone desanding

Desanding section is to remove sand out of starch slurry so as to improve the cassava starch taste.

Enrichment and purification

Using hydrocyclone station to remove protein, fine fibers and cell liquid out of slurry to improve the whiteness of starch. In the process of how to produce starch from cassava, hydrocyclone system is a cassava starch processing machine includes enrichment, recovering, purification and washing of starch slurry.

Dehydration

Starch slurry in starch jar after refined, and then remove moisture through peeler centrifuge. The wet starch water content after dehydration is 38—40%.

Starch drying

Flash dryer is adopted for drying starch. It can dry the wet starch fastly and entirely, make sure the cassava starch don't turn yellow, no spoil.

DOING cassava starch processing machine production capacity(per hour input cassava processing quantity):

4T/H, 6T/h, 10T/H, 12T/H, 20T/H, 40T/H. Count as daily output cassava starch quantity, it should be 20T/D, 30T/D, 50T/D, 60T/D, 100T/D, 200T/D.

Doing Company will offer the most suitable cassava starch processing machine production solution to you according to your situation.

Recommend reading: What can cassava be processed into

Cassava starch processing in Cambodia

Contact: Ms Elina

Tel: 0086 371 5677 1822

WhatsApp/Phone: +86 13526615783

Email: sales@doingmachinery.com

View more:

Garri processing machine

http://www.cassavaprocessing.com

How to produce starch from cassava

Cleaning and washing

Cassava cleaning process of how to produce starch from cassava usually adopts two machine: dry sieve and paddle washer to get a better cleaning effect, fully filter out the leafs, sand and other dirty on cassava.

The second is the grating

The cleaned cassava is pulverized by a grating machine, which blows the structure of the raw material in the process of how to produce starch from cassava, so that the tiny starch granules can be disintegrated and separated from the cassava roots. The starch has been substantially freed out and becomes a slurry mixture.

Cassava grating machine

Starch and residue separation

Separation is mainly used for removing fibers out of starch slurry in the process of how to produce starch from cassava. The efficient machines used for the separation of starch from cellulose fiber is the centrifuge sieve and fine fiber sieve. The starch slurry is put in a conical basket and centrifugal action separates the starch dispersion from the fibrous pulp.

Fine fiber sieve

Cyclone desanding

Desanding section is to remove sand out of starch slurry so as to improve the cassava starch taste.

Enrichment and purification

Using hydrocyclone station to remove protein, fine fibers and cell liquid out of slurry to improve the whiteness of starch. In the process of how to produce starch from cassava, hydrocyclone system is a cassava starch processing machine includes enrichment, recovering, purification and washing of starch slurry.

Hydrocyclone system

Dehydration

Starch slurry in starch jar after refined, and then remove moisture through peeler centrifuge. The wet starch water content after dehydration is 38—40%.

Starch drying

Flash dryer is adopted for drying starch. It can dry the wet starch fastly and entirely, make sure the cassava starch don't turn yellow, no spoil.

Flash dryer

DOING cassava starch processing machine production capacity(per hour input cassava processing quantity):

4T/H, 6T/h, 10T/H, 12T/H, 20T/H, 40T/H. Count as daily output cassava starch quantity, it should be 20T/D, 30T/D, 50T/D, 60T/D, 100T/D, 200T/D.

Doing Company will offer the most suitable cassava starch processing machine production solution to you according to your situation.

Recommend reading: What can cassava be processed into

Cassava starch processing in Cambodia

Contact: Ms Elina

Tel: 0086 371 5677 1822

WhatsApp/Phone: +86 13526615783

Email: sales@doingmachinery.com

View more:

Garri processing machine

http://www.cassavaprocessing.com

Comments

Post a Comment