What cassava processing equipment are needed in a large cassava starch processing plant?

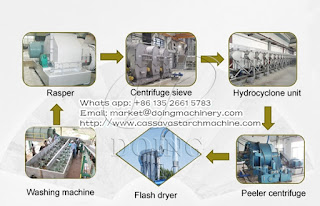

Generally, large cassava starch processing plant are equipped with whole set of cassava starch processing equipments, including dry sieve, paddle washing machine, cutting machine, rasper, centrifuge sieve, fine fiber sieve, desander, disc separator, hydrocyclone, peeler centrifuge, flash dryer, vibration sieve and packing machine. Next, I will introduce in detail the role of each cassava starch processing equipment.

Dry sieve: Dry sieve adopts multiple inner spirals structure design, through continuous stable rotation to push cassava raw material moving forward. During the process of pushing forward, the cassava raw material will rub against the inner spirals of the dry sieve, so as to remove the impurities attached on the surface of the cassava raw material.

Paddle washing machine: The design of the paddle washing machine adopts the principle of counter-current washing. During operation, the water in the cleaning tank will move in reverse with the material under the driving action of the rotor paddles. It further washes away the stubborn mud, sand and other impurities attached to the cassava.

Cutting machine: Cassava cutting machine is used for the first step of the cassava crushing section. The cutting machine is equipped with a high-speed rotating blades, which cut the cassava into pieces. Small pieces of cassava enter the cassava grinding process, and can effectively improve the grinding efficiency and effect.

Rasper: The function of the rasper is to completely crush the cassava. In the process of the operation, the rotor rotates at high speed and drives the saw blade to crush and grind cassava, turning cassava pieces into cassava pulp. A screen at the bottom of the rotor will screen out the starch particles that meet the requirements, while those that do not will be left in the rasper to continue grinding until they can pass through the screen.

Centrifuge sieve: Centrifuge sieve is a screening and washing equipment for cassava pulp. Under the action of centrifugal force and gravity, the cassava pulp is evenly distributed on the screen surface in the centrifuge sieve and moves along the screen in a complex curve, gradually reaching the edge of the screen basket. After washing with water, starch particles with diameters less than mesh hole fall out of the sieve, while starch particles with diameters greater than mesh hole are discharged by the slag pump.

Fine fiber sieve: Fine fiber sieve is mainly used to remove the fine fiber in the coarse starch slurry. When the fine fiber sieve is in operation, The driving system drives the roller to rotate at a constant speed, which drives the starch slurry to move on the roller. Then spray rinse starch granules, small starch granules can pass through the surface screen, and discharge from the aggregate mouth, while fine fiber and other impurities remain on the screen, and discharge from the slag mouth.

Desander: The desander uses the principle of centrifugal separation to remove sand in the cassava starch slurry, thereby reducing the ash content of the starch and improving the taste of the final product.

Disc separator:Disc separator is one of kind of settling centrifuge, which use centrifugal force to accelerate separating process. The main function of this cassava starch processing equipment is to separate the protein and cell fluid in the slurry, and to purify the starch slurry.

Hydrocyclone:The hydrocyclone is a necessary equipment for the cassava starch processing plant. The general process of full hydrocyclone includes three parts: concentration, recovery and refining. It uses the principle of centrifugal sedimentation to further remove the fine fiber and protein in the starch milk.

Peeler centrifuge: The peeler centrifuge adopts electrical-hydraulic automatic control, and dewaters and spins starch slurry through automatic control of feeding, separation, washing, unloading and net washing.

Flash dryer:Flash dryer adopts the principle of negative pressure drying. The high-speed hot air flow can disperse the wet material, stir and mix at the same time during the external dispersion process, and then the material and the hot gas flow in parallel. The two are in full contact and can exchange heat, then the starch is dried, and finally the dried starch is separated by the cyclone separator.

Vibration sieve:Vibration sieve is a kind of special type, high precision fine particle screening machine. The vibration sieve is equipped with various mesh screens, which can separate the different particles and powder materials continuously to meet different needs. After sieving, the finished cassava starch will be more refined and pure.

Packing machine:The name of the cassava starch processing equipment indicates that the purpose of the packing machine is to pack the finished starch. The operation process of the packaging machine is set by the program, controlled by the computer, and completed automatically. It is suitable for quantitative packaging of various industrial and agricultural powder materials.

The above is an introduction to the functions of each cassava starch processing equipment that a cassava starch processing plant needs to buy. Doing Holdings - Henan Jinrui Food Engineering Co., Ltd can provide all these cassava starch processing equipments for you. If you want to know more, please contact us.

Email: market@doingmachinery.com

http://www.cassavastarchmachine.com

Comments

Post a Comment